Temperature Controller Calibration Lab in Chennai | 8754432261

Temperature Controller Calibration Lab in Chennai – Metric Measurement Technologies is among the top-notch of Calibration lab in Chennai.

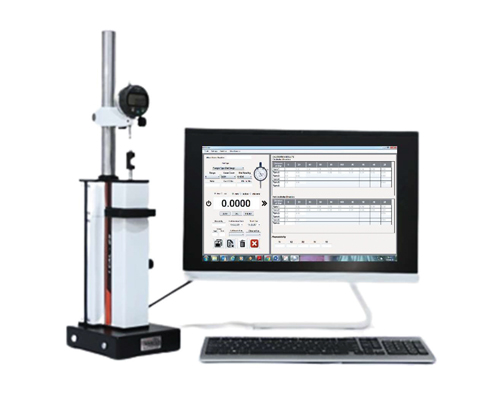

Temperature Controller Calibration Lab in Chennai – Metric Measurement Technologies is a best and leading Laboratory operating under the Venture of M/s. Metric Measurement Technologies-Chennai. The laboratory is functioning in Quality Management systems requirements and are aligned with its pertinent standard requirements in the field of Electrical, Pressure, Mass, Dimension, Thermal and Chemical. The calibration laboratory rendering services for the both In-house and On-site. Give us a call! We’re here for you. +91 8754432262.

Calibration Lab in Chennai

The Calibration Laboratory is operating with highly qualified and trained personnel and the Measuring Standards needed for Calibration are Purchased, Owned, and Maintained and regularly calibrated which are fully Traceable to the International System of Units (SI) through various Government bodies.

Temperature Controller Calibration Lab in Chennai

Trusted Storage Tank Inspection, Audit and Calibration From a Leading Supplier

As a leading supplier of inspection, audit and calibration services, we offer you unparalleled expertise, state-of-the-art technology and a global reach. That is why we are the first choice for clients needing to ensure safe storage of everything from chemicals and petroleum products to liquefied gases.

We offer you a comprehensive range of services for both underground storage tanks (UST) and above ground storage tanks (AST). Our storage tank inspection, audit and calibration services include:

- 3D modeling of tank floor and shell

- Assessment of water and sludge inside containers

- Assessment of subsoil corrosion

- Automated tank floor measurement

- Environmental impact studies and risk analysis

- External thickness measurements and calculation reviews

- Hydrotest

- Identification plate stamping and adjustment

- Non-destructive testing (NDT)

- Project management and construction supervision

- Tank floor volume measurement

- Tracing of system leaks and assessment of material strength

- Ultrasonic density tests

- Welding procedures and qualification to international standards

Contact us today and find out how our storage tank inspection, audit and calibration services can ensure the safety and integrity of your storage tanks.

Calibration may be required for the following reasons:

- a new instrument

- after an instrument has been repaired or modified

- moving from one location to another location

- when a specified time period has elapsed

- when a specified usage (operating hours) has elapsed

- before and/or after a critical measurement

- after an event, for example

- after an instrument has been exposed to a shock, vibration, or physical damage, which might potentially have compromised the integrity of its calibration

- sudden changes in weather

- whenever observations appear questionable or instrument indications do not match the output of surrogate instruments

- As specified by a requirement, e.g., customer specification, instrument manufacturer recommendation.

Give a Missed Call at +91 87544 32262 or Chat with us!

Why Choose Metric Measurement Technologies

Best Temperature Controller Calibration Lab over the Areas in Tamil Nadu

Trichy | Madurai | Puducherry | Coimbatore | Hosur | Sholinghur| Ranipet | Gummidipoondi | Vellore |

For More Visit our Location on Maps