Dial Calibration Tester Suppliers in Coimbatore, Hosur and Sholinghur | 8754432261

Dial Calibration Tester Supplier in Coimbatore,Hosur and Sholinghur – Metric Measurement Technologies offering dial calibration & testing services to meet your requirements.

Dial Calibration Tester Suppliers in Coimbatore, Hosur and Sholinghur – Metric Measurement Technologies is a best Dial Calibration Tester supply is a comparison between a known measurement (the standard) and the measurement using your instrument. Typically, the accuracy of the standard should be ten times the accuracy of the measuring device being tested. However, A dial calibration tester accuracy ratio of 3:1 is acceptable by most standards organizations. Sure Controls provides preventative field service to help you ensure your instruments and controls are accurately calibrated.

Calibration for your Dial Measuring Tester

Calibration of your dial measuring instruments has two objectives: it checks the accuracy of the instrument and it determines the traceability of the measurement. In practice, calibration also includes repair of the device if it is out of calibration. A report is provided by the calibration expert, which shows the error in measurements with the measuring device before and after the calibration.

Feel free to contact us: +91 87544 32261, today for more information on our products and supply. Browse through our website and see what we offer our clients. We guarantee that our supply is of the best quality that can be found today.

Dial Test Indicator Calibration in Coimbatore, Hosur and Sholinghur

Purpose: The purpose of this procedure is to provide general instructions for the calibration of dial test indicators.

Scope : All standard dial test indicators used to measure, gage, test, inspect and control part compliance to customer specifications and drawings.

Procedure

- Preliminary Instructions and Notes

- Read this entire procedure before beginning the calibration.

- Calibration shall be performed in an environment that conforms to Manufacturer Specifications.

- The dial test indicator will hereafter be referred to as the Instrument Under Test (IUT).

- Verify that the IUT is clean.

- Visually examine the IUT for any condition that could cause errors in the calibration.

- An error in zero setting during calibration will be contained in every measurement and will increase in proportion to the distance from zero.

- If any of the requirements cannot be met, refer to the applicable manufacturer manual.

- If a malfunction occurs or a defect is observed while calibration is in progress, the calibration shall be discontinued and necessary corrective action taken; if corrective action affects a measurement function previously calibrated, the function shall be recalibrated before the remainder of the procedure implemented.

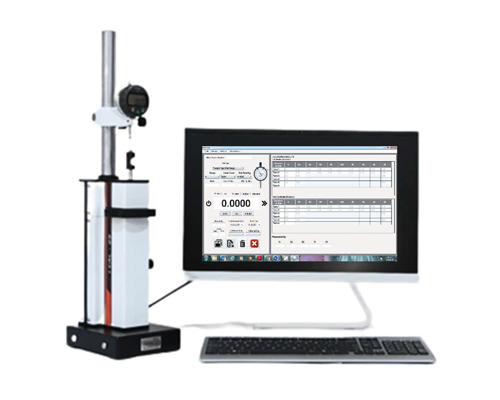

It’s based on Abbes’ principle and is used for calibration of Dial Gauges (Plunger & Lever type) and Bore Gauges. It has replaceable probe, so dedicated probe as master is not required.

- Calibration of Dial gauges (Plunger & Lever Type) and Bore Gauges

- Suitable for 0.01 and 0.001 mm (Least count 0.01 mm not covered in the scope of IS 2092)

- Interface with a computer for DG Cal Software

- Graphical presentation for errors in both directions

- Measuring Travel : 0-25 mm / 1 inch

- DCT 1 Repeatability : 0.0003 mm on Sylvac Display Unit with P25 probe

- DCT 2 Repeatability : 0.001 mm on Sylvac Dial

Give a Missed Call at +91 87544 32262 or Chat with us!

Why Choose Metric Measurement Technologies

For More Visit our Location on Maps